Aviation Industry in MAPNA Group

Services and Products

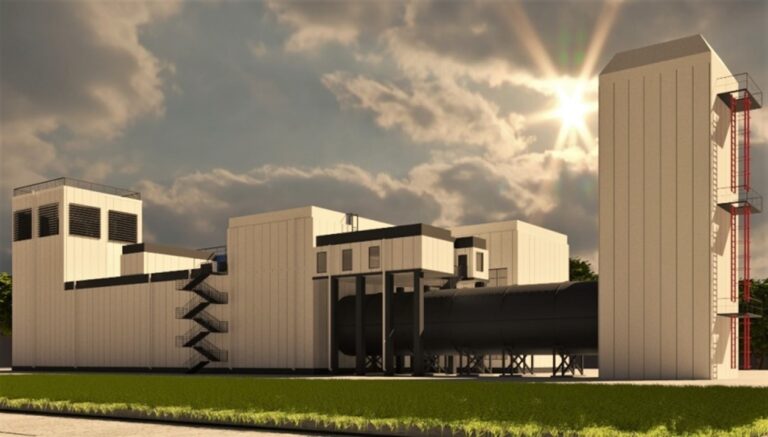

MAPNA Group’s activities in the aviation industry focus on two main areas: the maintenance and repair of aircraft engines, and the design and manufacture of necessary parts and tools. We offer services such as engine maintenance, repair and overhaul, parts repair, the establishment of test cells and related laboratories, and engine leasing. In addition, the group can design and manufacture various parts and tools for the aviation and airport industries.