On Saturday, the contracts were formally signed in a ceremony attended by the Minister of Roads and Urban Development, the CEO of Iran Railways, the Governor of Yazd, the CEO of IDRO, and the President of MAPNA Group.

These agreements link Iran Railways with MAPNA and private sector firms to strengthen both freight and passenger rail assets.

The first contract commits MAPNA to deliver 40 MAP-30 heavy freight locomotives, valued at 9,500 billion Iranian tomans. It is described as the largest domestic locomotive order in Iran’s history. Production is to take place at MAPNA’s Locomotive Engineering and Manufacturing facility.

A second contract covers the overhaul of 37 Iran Safir (Siemens) passenger locomotives, worth 2,500 billion tomans. These machines, originally built under Siemens or under license by MAPNA, will be refurbished at MAPNA Railway Maintenance and Operation Development Company (MRM).

In parallel, a memorandum of understanding was signed between Yazd Rail, MAPNA and Iran Railways to support in-country manufacturing and reduce imports for 50 passenger wagons, with production planned at MAPNA’s Wagon Pars facility.

Minister lauds MAPNA’s skilled experts

The minister underlined government backing for private sector-led infrastructure projects. She recalled her visit last winter to MAPNA’s locomotive manufacturing plant.

She said she had observed “young elites and skilled experts who, despite the difficulties, remain committed to this homeland,” a commitment she called essential to national development.

She reiterated: “All these projects are implemented domestically and by the private sector.”

The project expected to yield some $163m return

Head of Iran Railways, Jabbar-Ali Zakeri, noted that the agreements aim to support domestic capability in locomotive and wagon production, reduce dependency on imports, and boost the share of rail in passenger and freight transport.

He projected that these deals will yield a 10 percent increase in freight traction capacity, a 30 percent increase in passenger traction capacity, and a 5 percent rise in passenger transport capacity.

Zakeri also outlined the estimated social and economic benefits of the projects, noting that the total social return was valued at around $163.9 million. He said fuel savings were projected at approximately $53 million, while accident reduction was expected to yield about $70 million in benefits. The initiatives were also estimated to save $14.5 million in climate-related costs, reduce road wear by roughly $7.3 million, and lower environmental pollution by an additional $19 million.

85 percent of the locomotives produced domestically

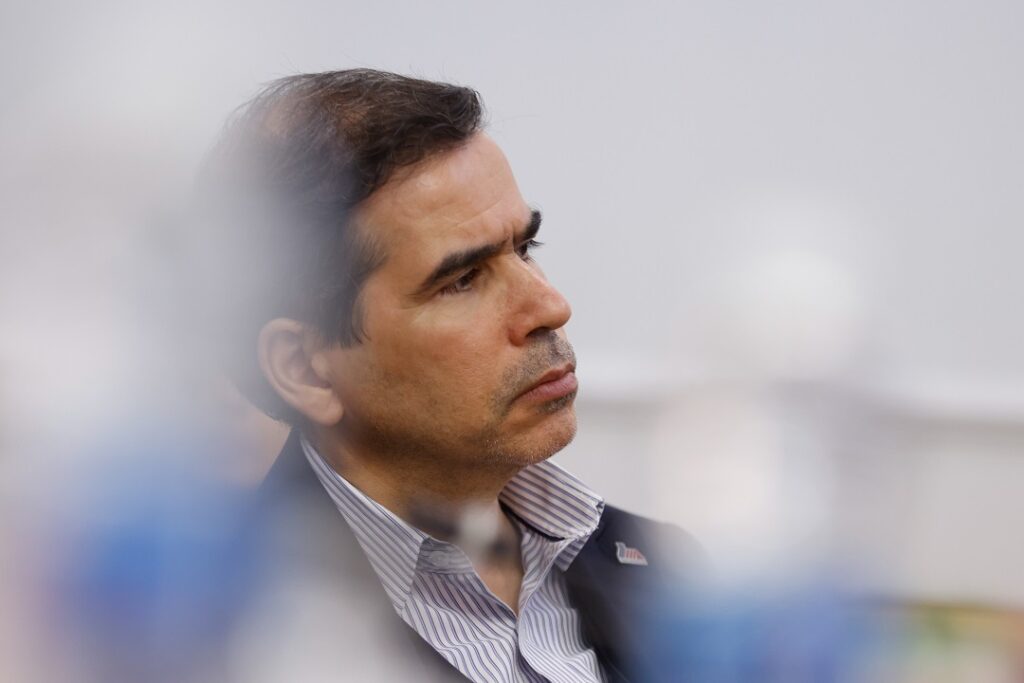

MAPNA Group President Mohammad Owliya said the new rail contracts will improve the country’s rail infrastructure and asserted that 85 percent of locomotive parts will be produced domestically, helping cut import dependence.

He traced MAPNA’s rail activity back to the contract for 150 Iran Safir (Siemens) passenger locomotives, which he said laid the foundation for locomotive manufacturing in Iran.

He recalled the minister’s plant visit last winter and her emphasis on internalization of rail sector needs. He said that the industry has now reached a stage where “85 percent of the locomotives in this contract are domestically produced and the import share is only 15 percent.”

Owliya added that the projects will also stimulate employment and help create a domestic supplier network. He said the contracts will be executed over 14 to 29 months, reflecting careful planning.

At the close, he proposed that the government allocate some of its approved special deposit bonds for rail procurement and provide guarantees tied to Iran Railways to facilitate financing. He stated that such backing would reduce investment risk.

MAPNA Group runs a comprehensive rail division, covering design, engineering, procurement, operations, and investment in railway projects.