MAPNA’s Model for Sustainable Development and Water Resource Management

MAPNA’s Model for Sustainable Development and Water Resource Management

MAPNA Group has expanded into the water sector, investing in desalination, wastewater recycling and agricultural water efficiency as Iran confronts mounting water stress.

In recent years, MAPNA—a conglomerate best known for its energy and infrastructure ventures—has begun an active push into the water industry. As Iran faces severe water scarcity and rising pressure on its limited resources, the participation of capable private actors has become more imperative.

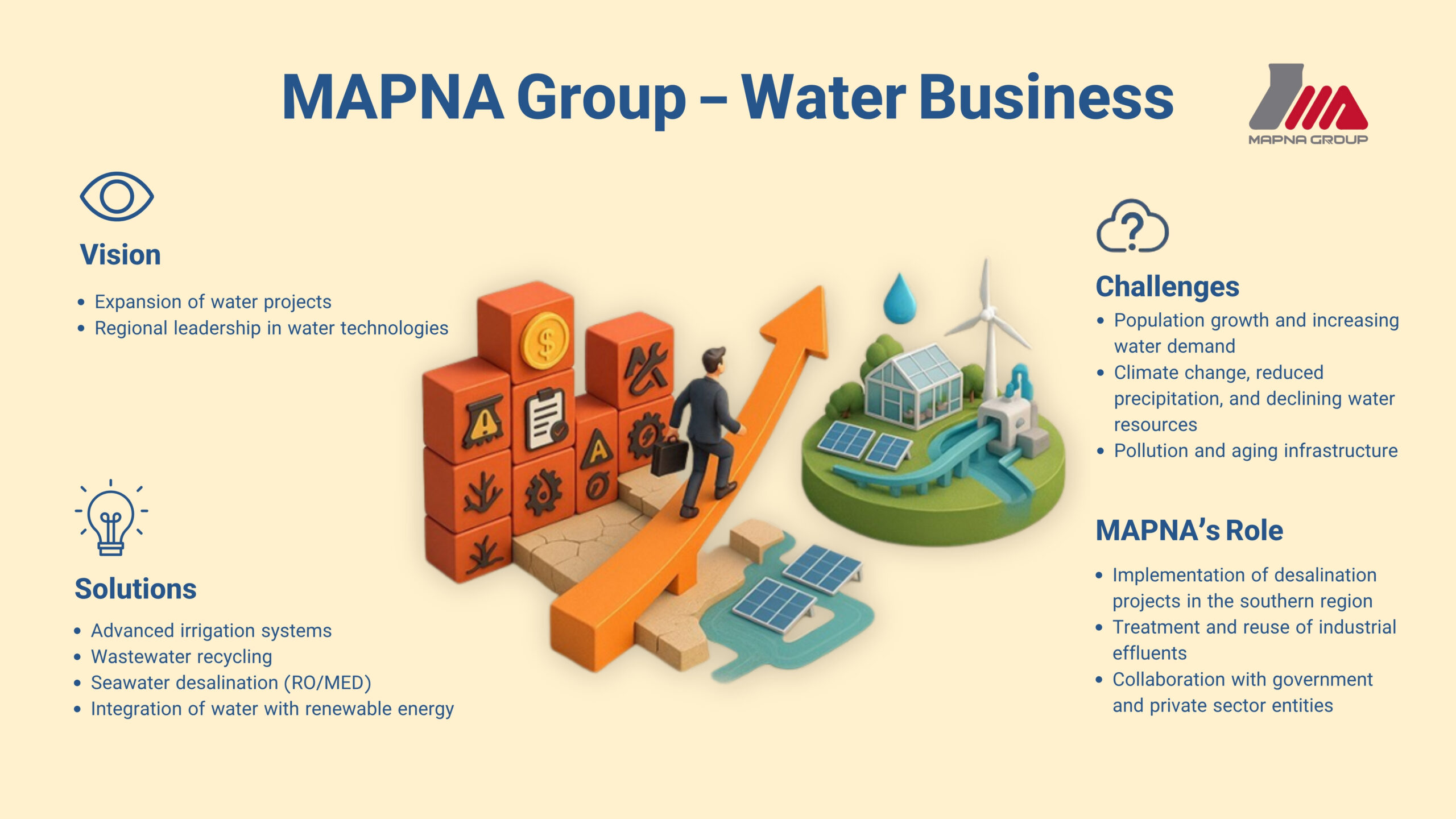

MAPNA’s water business is built around three pillars: desalination and seawater transfer, industrial and municipal wastewater reuse, and smarter water use in agriculture. These areas not only respond to urgent national needs but also have the potential to support sustainable development within Iran and across the region.

In a discussion with MAPNA’s media office, Mohammad Reza Ghasemi, CEO of MAPNA’s Water Business, described Iran’s climate as largely arid to semi-arid, noting the country’s average annual rainfall is about 250 mm—roughly one-third of global norms.

He warned that Iran’s medium-term water supply outlook is fraught with difficulty, in part because nearly 90 percent of the country’s water is used in agriculture under low-efficiency methods.

Industrial and household water demand is smaller in share but growing rapidly. Ghasemi cautioned that without smarter strategies and shifts in consumption patterns, the water crisis may deepen.

When asked what role MAPNA expects to play in this domain and what narrative drives its water business within the broader industrial conglomerate, Ghasemi laid out how the company leverages its engineering and technical assets to contribute solutions.

Technological capacity and strategy

Ghasemi said MAPNA views the water crisis as one of Iran’s largest national challenges, and the group—as an industrial and technology enterprise—cannot remain indifferent.

He cited two motivations for MAPNA’s entry into water: first, the country’s need for technological solutions in water resource management; second, the opportunity to deploy MAPNA’s existing engineering expertise in a sector closely linked to energy.

He noted, “We now have valuable experience in seawater desalination technologies. In parallel, we have invested in the development of advanced industrial and urban wastewater treatment.”

He said the aim is to combine these approaches to generate new potable and industrial water while easing strain on natural sources. Ghasemi added that Iran’s Seventh Development Plan (issued July 2024) mandates that over its five-year span, the annual capacity of “nonconventional” water sources be boosted by at least 1.774 billion cubic meters.

Projects: desalination and reuse

Ghasemi described MAPNA’s water project portfolio, which ranges from large reverse-osmosis and thermal desalination plants on southern coasts to urban and industrial wastewater treatment installations.

He named Bushehr (Lian) Desalination Plant as one of the salient projects that uses the reverse osmosis (RO) technology to produce water for some 200,000 people in the city, which sits near the Persian Gulf.

The thermal desalination plant of Qeshm Water and Power Company currently supplies up to 18,000 cubic meters of drinking water per day to the Qeshm Island urban water network, he said, adding that part of the output is also bottled and distributed under the “Mangro” brand across Hormozgan Province and several neighboring provinces.

He cited the Makran Desalination Plant, currently under construction near Chabahar, which will yield up to 40,000 cubic meters per day.

Other ongoing desalination projects, he continued, includes the thermal desalination plant at the Mehr Persian Gulf Refinery with a capacity of 6,000 cubic meters per day, the RO desalination unit in Dayyer with a capacity of 3,000 cubic meters per day, and the Charak desalination plant with a capacity of 8,000 cubic meters per day.

In addition, MAPNA Group is actively engaged in wastewater recycling at industrial-grade standards. For instance, at Parand and Ferdowsi (Mashhad) power plants, both owned by MAPNA, wastewater from neighboring cities is collected, transferred, and undergoes advanced treatment to produce demineralized water. This water is then reused in power generation cycles to improve plant efficiency, he noted.

These initiatives, Ghasemi continued, have become “successful models for the power sector and other industries.”

Similarly, a project at Esfahan Steel Company (ESCO), now nearing completion, treats municipal and industrial wastewater for reuse in steel production. “This approach provides two key benefits: it reduces industrial dependence on freshwater sources and eases pressure on underground and surface water reserves,” he added.

Agriculture and efficient irrigation

Agriculture remains the largest water consumer in Iran. Ghasemi said MAPNA is developing intelligent hydroponic greenhouse systems that deliver precisely the water needed by crops.

Though currently in pilot form, these systems could be scaled nationally to boost water efficiency, noted Ghasemi.

He cited a pilot project named MAPNA AGREED, near the Genaveh power plant, consisting of three greenhouses across one hectare powered by a 660 kW solar panel array—an innovative effort to combine agriculture, water efficiency, and clean energy.

Environmental safeguards and reuse challenges

Ghasemi emphasized that wastewater recycling must be handled carefully to prevent chemical or microbial contamination from entering the cycle. He noted that industrial effluent may contain heavy metals or toxic agents, making multi-stage treatment and advanced processes such as MBR (Membrane Bioreactor) essential.

He affirmed that MAPNA is committed to aligning with higher-level regulations—particularly those in Iran’s Seventh Development Plan—on expanding use of unconventional water sources in water-intensive industries (excluding food and hygiene sectors). This, he said, will relieve pressure on surface and groundwater reserves.

Challenges ahead

Ghasemi acknowledged some barriers at the national and organizational levels. These include limited financial resources, aging infrastructure, regulatory and bureaucratic complexity, and the unpredictability posed by climate change and drought.

Within MAPNA, he cited difficulties securing project financing, technical challenges, and constraints imposed by international sanctions.

He added that many advanced technologies still depend on imported inputs. But he noted that MAPNA has localized a significant share of its equipment and, with cooperation between domestic firms and selected foreign partners, has managed to sustain project lifecycles.

Outlook and ambitions

Looking ahead three to five years, Ghasemi said MAPNA will prioritize expansion of desalination, seawater transfer, and wastewater reuse, as well as elevating agricultural water productivity.

These initiatives are “critical” for municipal water supply and industry, he stressed.

He expressed MAPNA’s intention to become a stronger actor in regional water markets, noting that neighboring countries face similar water constraints. By leveraging its technical competencies, MAPNA aims to extend its reach beyond Iran and emerge as a significant water infrastructure provider in the region.

Ghasemi said MAPNA’s purposeful entry into the water sector demonstrates that it is more than an energy company—it is evolving into a broader infrastructure and resource management entity.

With its desalination, reuse, and agricultural water efficiency projects, MAPNA offers solutions to immediate national water stress. More broadly, these efforts could serve as a development model for water-scarce nations.

He concluded that despite economic and technical hurdles, the future of MAPNA’s water business appears promising.