Distributed Control System (DCS)

MECO provides various solutions for automation and control of different processes in industrial sites, especially power plants and oil and gas sites. These solutions include systems under SPPAT2000-3000 license and domestically-manufactured MAPCS distributed control system.

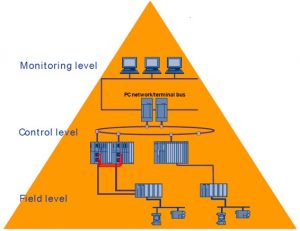

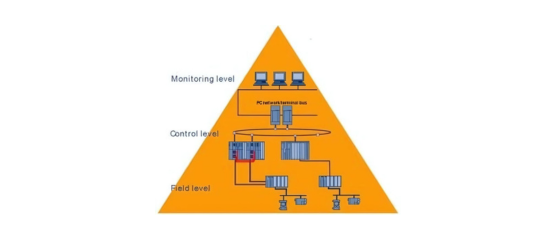

A distributed control system in large industrial sites consists of the following components:

Instruments/actuators are the devices that measure or control the process variables, such as temperature, pressure, flow, level, etc. They are connected to the controllers using one or more types of Field Bus technologies, such as Foundation Field Bus, DeviceNet and Profibus. The Field Bus reduces the cable usage by allowing many devices to share a single interface cable.