The certificate was formally granted to MAPNA Combined Cycle Power Plants Construction & Development Company (MD-2) on September 20, 2025.

With this milestone, MAPNA’s MD-2 has now delivered 129 power plant units across the country, reaching a combined capacity of 20,168 megawatts.

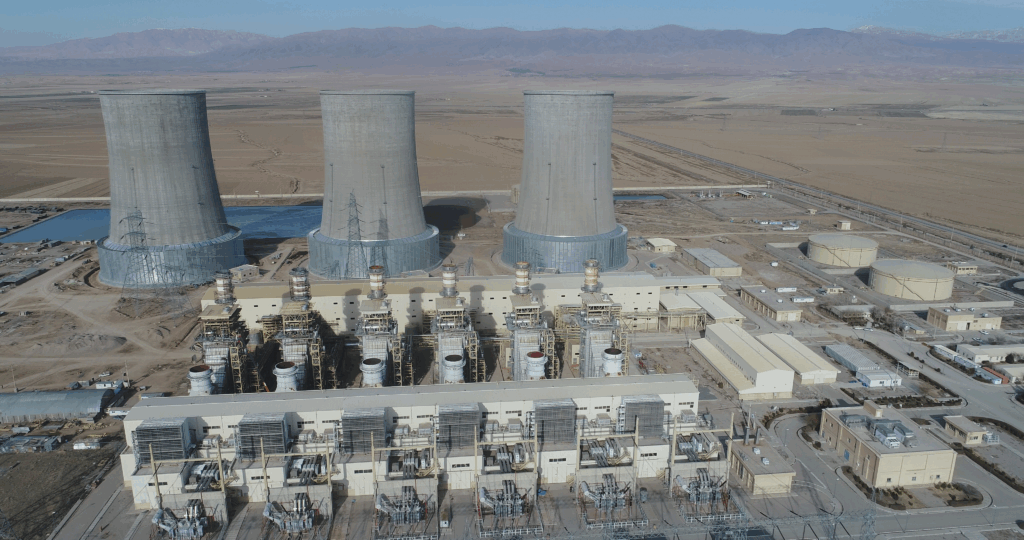

The Shirvan project is located 15 kilometers southeast of the city in North Khorasan Province. Its three steam units, each with a capacity of 160 megawatts, are equipped with E-Type turbines produced by MAPNA’s turbine engineering arm, TUGA. The plant also incorporates heat recovery steam generators with supplementary firing, a dry Heller cooling system with a concrete tower, and an electrical substation with 400/132-kilovolt transmission lines handled under the employer’s scope.

The project’s client is Iran’s Thermal Power Plants Holding Company, while Moshanir acted as consultant and supervisor on behalf of the employer.

The Shirvan plant is part of the broader “22-Unit Combined Cycle Project,” a contract signed in 2002 between the Thermal Power Plants Holding Company, under the Ministry of Energy, and MAPNA Group. The agreement covered design, engineering, equipment supply, civil works, installation, and commissioning of combined cycle plants in multiple cities, including Neka, Yazd, Kazerun, Kerman, Damavand, Sanandaj, Shirvan, Abadan, and Jahrom.

Combined cycle design is central to the project’s efficiency. Exhaust gases from gas turbines are channeled into heat recovery steam generators, which in turn produce steam to drive the steam turbines. This process raises efficiency from about 33 percent in simple cycle plants to nearly 50 percent, cutting fuel consumption and reducing emissions.

The Shirvan development also reflects MAPNA’s long-term strategy of expanding local expertise in power plant construction and technology.

By producing key equipment domestically and transferring technology in cooperation with global partners such as Siemens, MAPNA has lowered costs compared with full reliance on imported systems while also generating direct and indirect employment in several provinces.