Gas & Steam Turbine Governor Control System

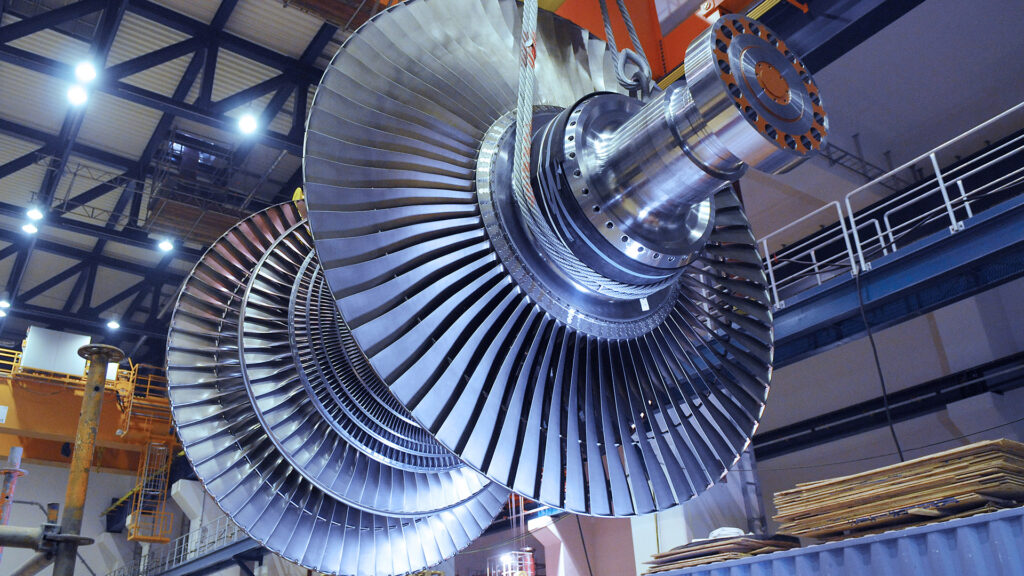

Turbines can be classified into two types based on their power source: gas and steam. In a gas turbine, gas combustion at high pressure and temperature creates the driving force to rotate the blades. In a steam turbine, superheated water vapor at high temperature and pressure spins the blades. In both types of turbines, thermodynamic parameters such as pressure, temperature, velocity and fluid flow can change or fluctuate rapidly, and without proper control strategies, they can cause equipment damage and even personnel injuries.

Turbines are also complex machines that consist of various components such as fuel system, oil system, cooling systems, control valves, etc. These components have different levels of sensitivity and response time. Therefore, turbine control strategies are divided into two separate categories.

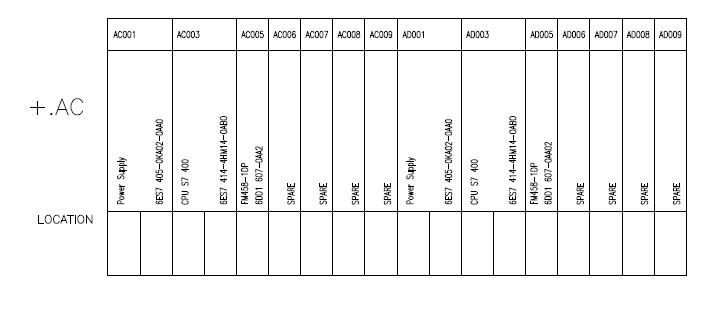

The first category covers the normal control functions for the turbine secondary equipment, and is usually performed in the plant’s DCS system. The second category, which is more important and sensitive, controls the internal parameters of the turbine such as speed, temperature, pressure and output power, and is represented by a separate control package called the governor system. The turbine governor system must respond quickly, ensure safety, and have special design and construction standards.

MAPNA Electric and Control Engineering & Manufacturing Company (MECO) specializes in the design and construction of power plant’s control and electric systems based on an agreement with the German company Siemens to transfer the know-how in design and manufacturing of gas and steam turbines governor control system.projects.