Fuel Control System (For Turbine)

Turbine is one of the most important equipment that is used as a prime mover, i.e. as a device that converts the chemical energy of the fuel into mechanical energy. In power plants, this mechanical energy is used to drive the generator and produce electricity.

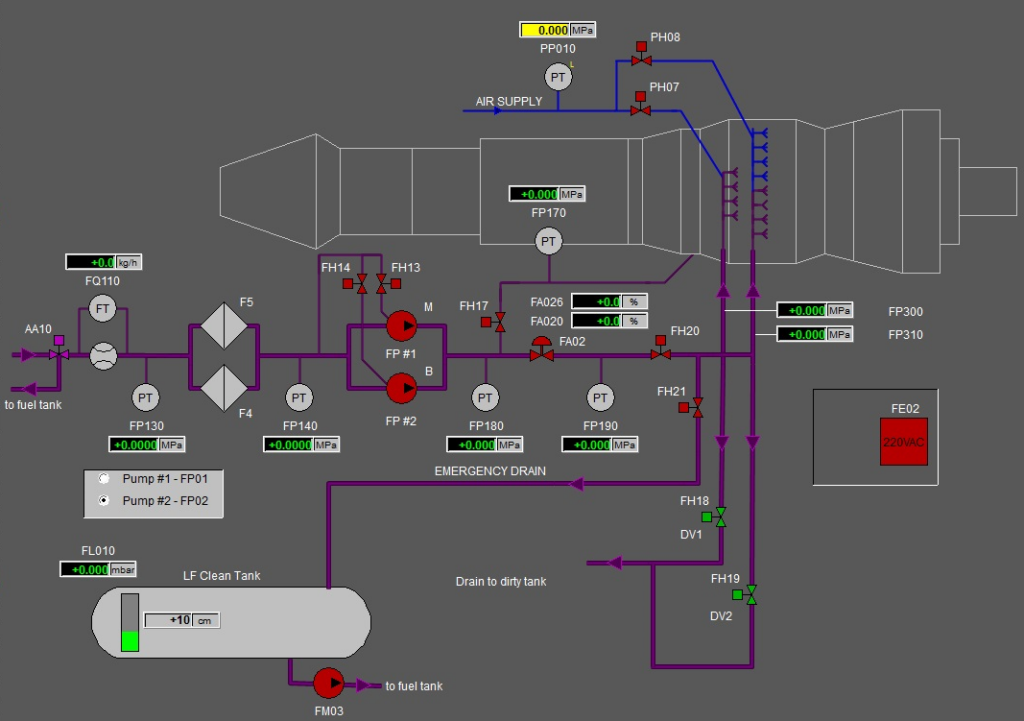

The turbines used by MAPNA Group can work with two types of fuel: natural gas and liquid fuel. The choice of fuel depends on the climatic conditions, the availability of natural gas sources, and other factors. The fuel control system is responsible for controlling the amount of fuel needed to produce the desired energy in the turbine. This is very important because the fuel used in power plant turbines has a very high volume and energy, and if it is not delivered to the turbine in the right amount, it can cause equipment damage and even fire and explosion. Therefore, the turbine fuel control system must have special features and operate very accurately and safely.

Since two types of fuel are used in turbines, the fuel control system must be able to control both types of fuel, each of which has its own features and calculations. The system must also be able to switch between the fuels (from gas to liquid or vice versa) without any interruption in the electricity production, if necessary. The turbine fuel control system is part of the turbine control system, which controls other aspects of the turbine operation as well. Such control systems are among the main products in MECO’s portfolio, as turbines are essential for various industries such as oil, gas, petrochemical and power plants. Siemens equipment is usually used in turbine fuel control systems.