Features

MAPNA’s Upgraded Gas Turbines: A Quantum Leap in Power Industry

MAPNA Group has been working hard to up its game in the power sector through a multitude of strategies, with the aim of outperforming rivals via superior products and services.

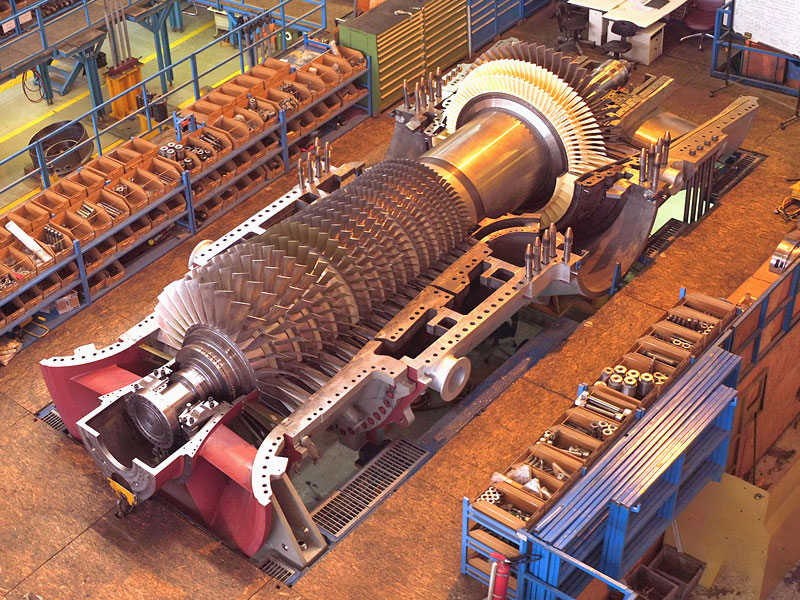

The Group has cast a special focus on gas turbines, which have captured a significant portion of the industrial prime-mover market, and developed MGT-70 (3), a product of its MAP2B R&D project.

MGT-70 (3), which features cutting-edge design and manufacturing technology, has already found a considerable market in Iran, giving MAPNA Group the potential to enter the fierce competition with internationally renowned brands. The new achievement has also provided the grounds for the corporate to set foot in the regional and international power projects.

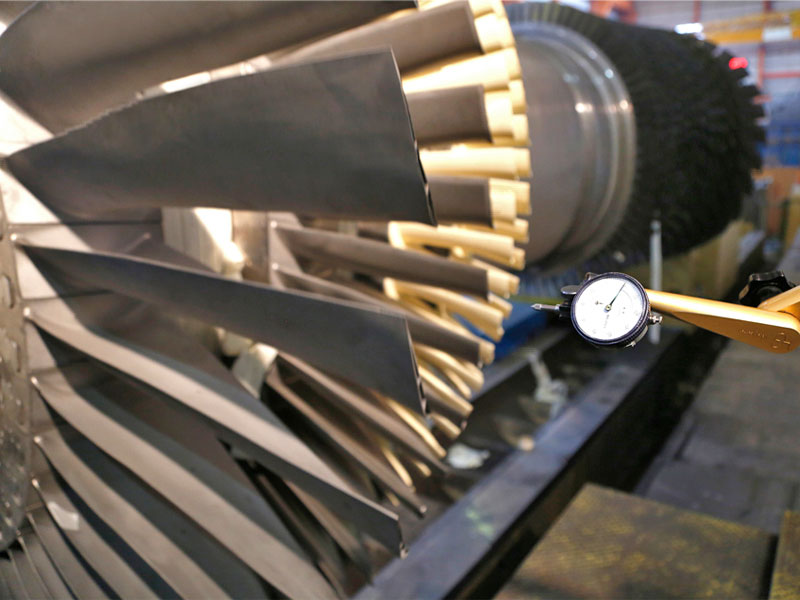

MGT-70 (3) is a competitive E-class gas turbine with 185-MW power output capacity and efficiency rate of 36.4% at ISO conditions.

Class-E turbines continue to play a unique role in the global market. In Iran, the use of Class-E turbines has greatly contributed to the country’s electricity generation capacity, alleviating the power shortage problems lingering throughout the 1980s and 1990s. Installed anew or upgraded from older versions, Class-E turbines have played a stronger role in Iran’s power generation in the recent years.

MAPNA has developed the expertise to design and manufacture E-Class gas turbines over the course of more than two decades of close collaboration with international partners and use of skilled and qualified human resources inside the country. This has aided the Group push with its development plans and address the country’s electricity woes.

The importance of adopting this strategy was revealed a decade later (in the 2010s) when international circumstances hampered the activities of many economic sectors but had little effect on the electricity sector. Thanks to indigenized expertise and technologies in knowledge-based companies such as MAPNA Group, the Iranian electricity sector has been able to resolve a large portion of those challenges.

MAPNA Group is the first Iranian company in the Middle East and North Africa (MENA) region to acquire the skills and experience necessary to build key power plant equipment such as gas and steam turbines, hot sections of gas turbines, generators, boilers, and electrical and control systems. In this regard , the Group launched a project in 2011 to update and improve the efficiency of E-class V94.2 turbines.

The project, which aimed to boost the capacity and efficiency of the national power grid, was carried out in three phases in six years. MGT-70 (3), a fruit of the MAP2B project, was unveiled in 2017.

Reliability and availability for power generation are two major requisites in the oil, gas and petrochemical industries. The MGT-70 (3) gas turbine has a number of characteristics that can help it meet those challenges, including robustness and long-term services.

These changes boost the V94.2 turbines’ power generation from 157MW to 185MW and increases their efficiency from 32% to 34%.

The MGT-70 (3) Gas Turbine meets customer requirements for economic installation and operation and provides excellent flexibility for industrial processes.

ate solutions, life and performance upgrades, and other lifetime services for these machines.

In Iran, there are 180 active V94.2 Gas Turbines that can be upgraded to the MGT-70 (3); this would increase the country’s electricity production capacity by a total of 5,000MW at a far lower cost than building power plants of equivalent capacity.

Upgrading these turbines will also help save fuel, cut pollution, generate more electricity, lower maintenance costs and prevent capital flight.

The turbine has highlighted MAPNA Group’s capacity to compete with domestic and international competitors. For instance, the MGT-70 (3) helped MAPNA Group to secure a contract for construction of the 3000-MW Rumaila Power Plant in Basra, Iraq. The 2-billion USD contract, the largest in Iran’s technological export history and the first of its kind to receive a sovereign guarantee from the Iraqi government, would not have been signed if not for the MGT-70 (3) gas turbine’s capabilities.

Negotiations for the Rumaila project had started even before the trial of the first MGT-70 (3) turbine. It took the client, Shamara Holding Group, one year and a half of negotiations with MAPNA Group technicians, and consultation with a well-known international company, before it was convinced to use the new turbine in the project. Technological specifications of MGT-70 (3) were eventually approved by the technical consultant, and MAPNA Group started construction of Rumaila Combined Cycle Power Plant promptly afterwards.

Upon completion, the power plant will comprise twelve MGT-70 (3) gas turbines and six steam turbines. The first phase of the power plant, consisting of six gas-fired units, has been constructed and is already in operation, supplying electricity for Iraq’s second largest city.

One of the key reasons behind the MGT-70 (3) gas turbines’ success can be attributed to the use of cutting-edge technologies to track and evaluate the turbine’s real-time performance at MAPNA’s Parand Combined-Cycle Power Plant. These arrangements, along with numerous subsequent reports on the product’s efficient service, have given MGT-70 (3) a high level of reliability, allowing customers to be confident in its capabilities, quality, and performanc

Since all the stages of design, construction, assembly, installation, commissioning and operation of the machine have been conducted independently by MAPNA and its subsidiaries, the Group offers quality after-sales services, including parts supply, maintenance, repair and overhaul, at a reasonable price.

Such a major achievement has helped MAPNA Group to undertake further steps in developing gas turbines with cutting-edge technologies.

In parallel with the R&D operations on MGT-70, MAPNA Group is also working on development and commercialization of an array of products including MGT-40, MGT-30 (1), and MGT-30 (2) turbo-generators. Since 2015, MAPNA has been also working on the next generation of its gas turbines dubbed ‘MGT-75’ which is expected to become operational in 2021.

Industrial gas turbines have various types of applications. The most common applications are found in the oil and gas industries, including refinery and petrochemical plants, mining and cement industries, as well as industries requiring independent and dispersed power generation.